● Power system: Adopting Dongfanghong 4105 supercharged engine, with large reserve torque, strong power, and durable construction; low failure rate, simple maintenance, adapt to harsh working conditions such as high temperature and humidity underground. 1. In recent years, domestic engines have been mature and stable in technology. They use turbocharged engines, which are more suitable for working at high altitudes. They have sufficient air intake, sufficient combustion, stronger power, good emissions, and low roadway pollution, while imported engines are only natural suction. Gas engine, no supercharged and intercooled, insufficient intake air, not suitable for working at high altitude. 2. The engine is more cost-effective. The equipment working environment in the tunnel is bad (humidity, dust, etc.), labor intensity is high (8-20 hours/day), and untimely maintenance and other factors can easily cause early engine wear, black smoke, and power after one year. Problems such as descent need to be overhauled. Imported engine maintenance costs are high, the cost of a major repair ranges from 20,000 to 20,000 yuan, and some parts need to be purchased from abroad, and the waiting time is long; while the domestic engine assembly price is about 20,000 yuan, and the parts are versatile and the price is lower, Easier to purchase.

● Transmission system: Shantui 280 hydraulic torque converter, 20 power shift gearbox are used, and it is matched with a closed multi-disc wet brake drive axle for mining machinery with high speed ratio, which increases the wheel gear speed ratio , The first gear speed is slower; the wheel side gear has been increased from 4 modules of the original 2 ton loader to 5 modules of the 3 ton loader. Simply put, the wheel side of the 3 ton loader is changed to 2 tons. The car is more durable. And the half shaft and differential, main reducer, gearbox, torque converter, engine are less stressed and should not be damaged. The input torque is large, the transmission efficiency is high, the work is stable, and the low speed and large torque are realized, making the first gear shovel more powerful. The tires do not skid, the filling rate is high, and the work efficiency is high.

Compared with imported variable pumps and variable motors, domestic hydraulic torque converters and power shift transmissions have the following advantages: The engine does not need to work at a high speed all the time. It can independently adjust the throttle of the engine under full load and no-load conditions, autonomously control the working load of the whole machine, and save fuel. However, the equipment that uses variable pumps and variable motors works all the time. Maintain a high speed, no matter full load or no-load fuel consumption is relatively large, and the noise is large.

● Working system: using pilot control to make the work easier and more efficient. The use of dual steering cylinders for steering is more stable and reliable and has a lower failure rate than the single steering cylinders used by other manufacturers.

● Electrical system: It is designed to be waterproof and moisture-proof to adapt to wet conditions in underground mines.

● Brake system: The service brake is a multi-disc wet brake, and the parking brake is a spring brake and hydraulic release, which makes the brake safe and reliable. Wet brakes wrap the brake discs, brake calipers, and brake pads and lubricate them with oil. The mud, sand and water mixture cannot enter, avoiding damage to the brake components. Within two years, there is no need to replace the brake components, reducing the frequency of maintenance, and the braking effect is better. For equipment with variable motor, only one brake at the input end of the transfer case is used for braking. The main brake is to use the hydraulic circuit between the pump and the motor to block the brake. The impact on the pump and the motor is large, and the hydraulic pipeline is prone to occur. Rupture, causing the risk of brake failure.

● Exhaust gas purification system: adopts water filtration device + oxidation catalyst to achieve two-stage filtration. Exhaust gas is discharged in the form of water mist and quickly settles to the ground, which greatly reduces air pollution and protects the roadway environment and the physical and mental health of the driver.

● The engine air intake adopts an oil-bath air filter, which replaces the ordinary paper air filter (the paper filter element will be deformed and blocked due to the moisture in the intake air and lose the filtering effect), and there is no need to replace the filter element.

● The steel frame of the vehicle is thickened, and the rigidity of the vehicle is enhanced. The bucket blade is made of high-strength alloy steel, which is wear-resistant and shear-resistant. The V-shaped structure reduces the resistance of shoveling and has a longer service life.

● Smooth wear-resistant and puncture-resistant tires are used, and four tire protection chains are used to make the tires have a longer service life.

● Strong climbing ability, full load maximum climbing 16°, with the assistance of hoist, it can be used for excavation of slopes within 28°, instead of slagging machine.

● The rear frame of the machine can be disassembled into 5 parts, which is convenient for going down the well.

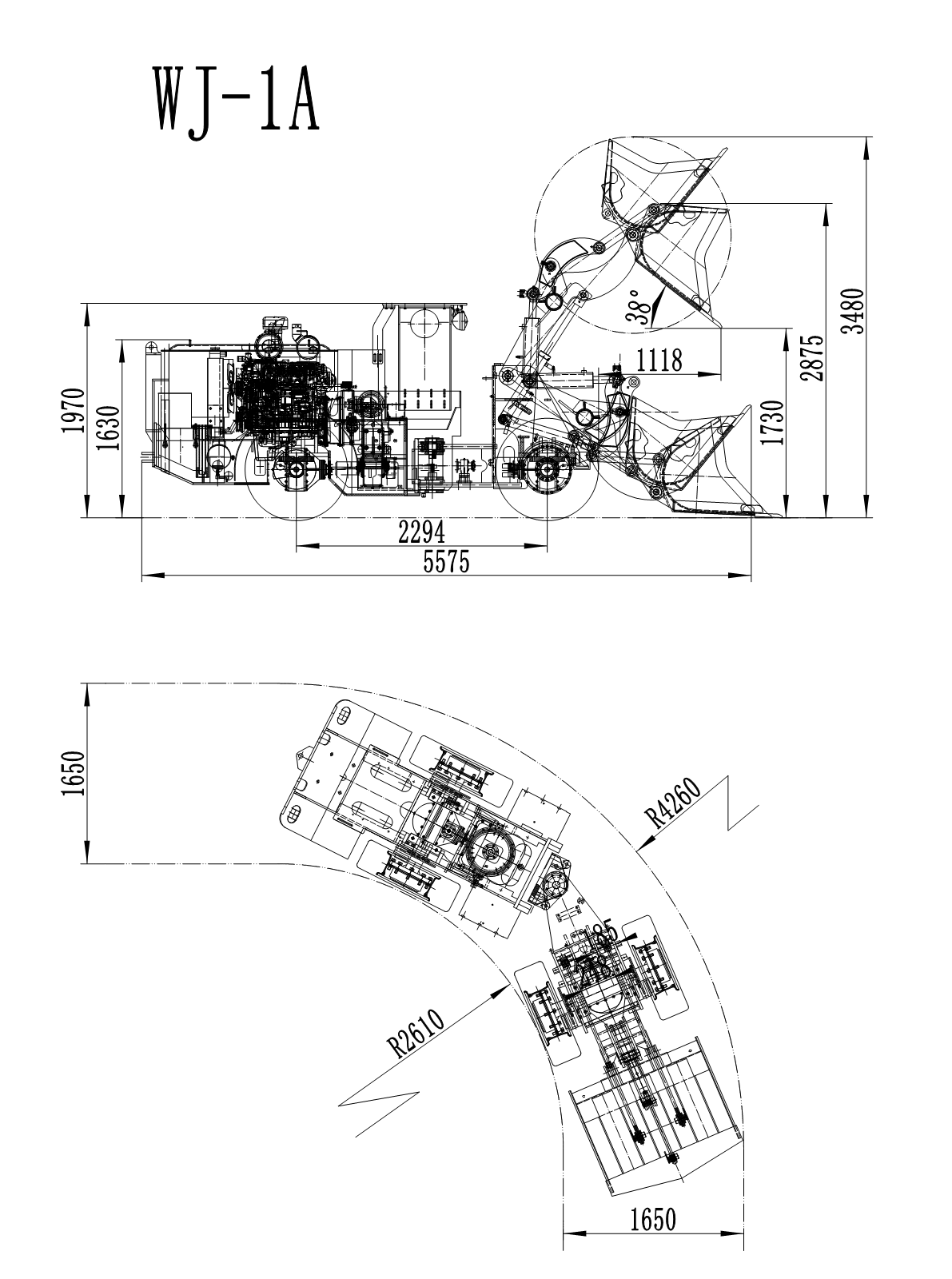

● The machine is compact in structure and easy to operate. It can perform integrated operations of shoveling, loading, transporting and unloading. It has high work efficiency and is suitable for mining and digging of roadways, as well as auxiliary operations such as construction and leveling of work sites and roads, and material transportation.

● 1.5-1.9 cubic bucket can be customized according to the proportion of ore. The output per shift is equivalent to that of other brands of 2 cubic scrapers, but the price is 30% lower than that of 2 cubic scrapers. The purchase cost is low, the use cost is low, and the cost performance is higher.

| No. | WJ-1.0 | Data |

| 1 | Bucket capacity (m³) | 1 |

| 2 | Rated load (T) | 2 |

| 3 | Operating weight (T) | 7 |

| 4 | Speed (km/h) | 0-9.5 |

| 5 | Forward gear (km/h) | I 0-5 II 0-9.5 |

| 6 | Reverse gear (km/h) | I 0-5 II 0-9.5 |

| 7 | Max. climbing gradient | 16° |

| 8 | Overall dimension (L×W×H mm) | 5700×1300×2000 |

| 9 | Min. turning radius (mm) | 4390 |

| 10 | Wheel base (mm) | 2242 |

| 11 | Wheel tread (mm) | 980 |

| 12 | Max. dumping height (mm) | 1700 |

| 13 | Dumping reach (mm) | 860 |

| 14 | Engine model | YTO LR4A3Z-22/ |

| 15 | Rated power (kW) | 68 |

| 16 | Tyre model | 9.75-18 |

China, factory, supplier, manufacturer, cheap, price, exporter, Chinese.

Rock mining | Coal mining | Mining technology | Underground mining machine | Mining shaft | Underground ming loader | Lhd loader | Dumping truck | Tunnel loader | Tunnel mucking loader | Tunnel mucking machine | Articulated dump truck | Tricycle dumper | Rock drilling machine | Underground drill rig | Road header machine | Tunneling machine | TBM machine | Shield machine | Electric digger | Concrete mixer pump

Sinosun Technology Group Co.,Ltd.

Address : Yuncheng Industry Zone, Heze City, Shandong Province, China

Tel : +86 530 6531227

Cellphone : +86-13561392361

Welcome to send your message to us